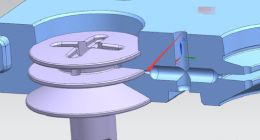

With customer’s requirement for batch qty and mold life, we will suggest mold material and cavities, some details like runner type, gate position, parting line location, ejector pin location will double check with customer.

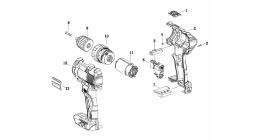

Once product design is confirmed, normally a prototype will be made to check their thickness, structure and assembly. Customer will check whether there is a need to improve or modify the drawing, double confirm before mold making, saving cost in mold modification.

Some customer only have product design and want to make mold with our company, firstly we will check the product design whether it is practical for mold making, and some details which may increase mold cost, we should figure out to make sure there is no misunderstanding. We treat every inquiry seriously and are responsible for our quote and every project.

To make sure customers can get their mold work smoothly when injection molding, normally will suggest making small batch (500-1000pcs) production in our factory, we will final check the mold and do the assembly check, save customers’ time and cost.

Will send customers samples together with size report and test assembly.

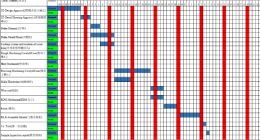

After all details of mold are confirmed, we will make a mold plan sheet with predict time for customer so that they are clear how long it will take for each step, every week will update the actual we already spent with some pictures and video, customer can react very fast according to our time table.

Mold will be cleaned with anti-rust oil and painted outside for longer mold life, considerable things like counter and mold lock will be assembled to the mold.