RYD MOLD Design Service

No matter product design or Mold design, our aim is to realize customer’s idea, turn the idea to be a practical drawing.

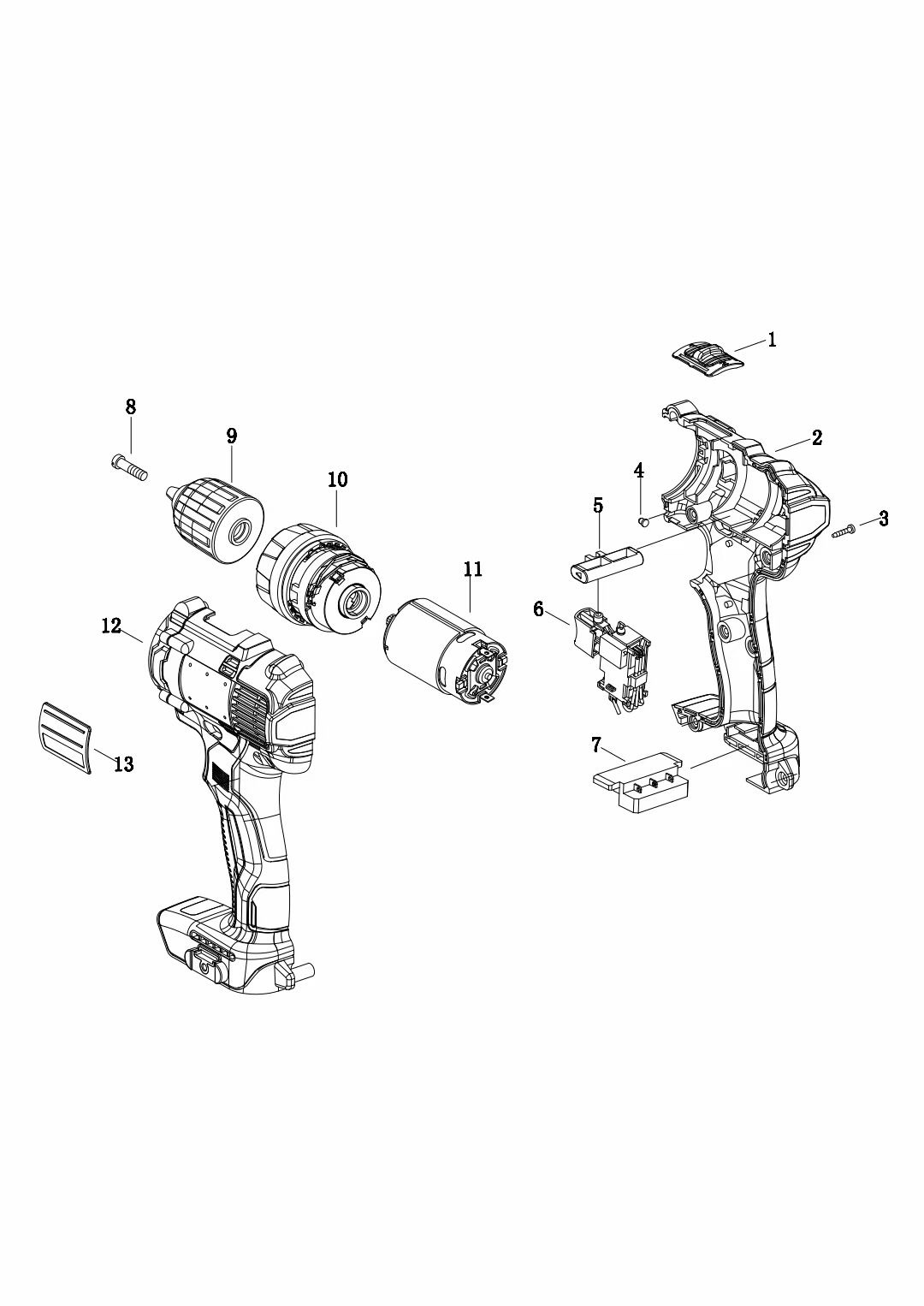

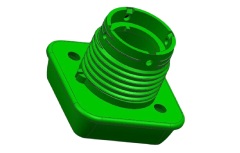

Based on your product definition creative concept from the design stage, our product designers will create, sketch and develop your product’s visual flow. The design process includes initial Cad design, mechanical engineering, electrical engineering, 3D Cad development, finite element analysis and stress testing.

Following your product definitions originating from a creative concept in the design phase, our product designers will create, sketch, and develop the visual flow of your product. The design process includes Initial Cad Design, Mechanical Engineering, Electronics Engineering, 3D Cad Development, FEA Analysis & Stress Testing

DFM Analysis Service allows product designers to identify and resolve any issues that may arise during the manufacturing phase to reduce costs. Depending on the type of manufacturing process, DFM practices have guidelines that help to precisely define various tolerances, rules, and common manufacturing checks.

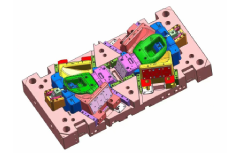

The mold design will be evaluated and communicated between RYD Mold and customers, until both of us reach an agreement on the mold design.

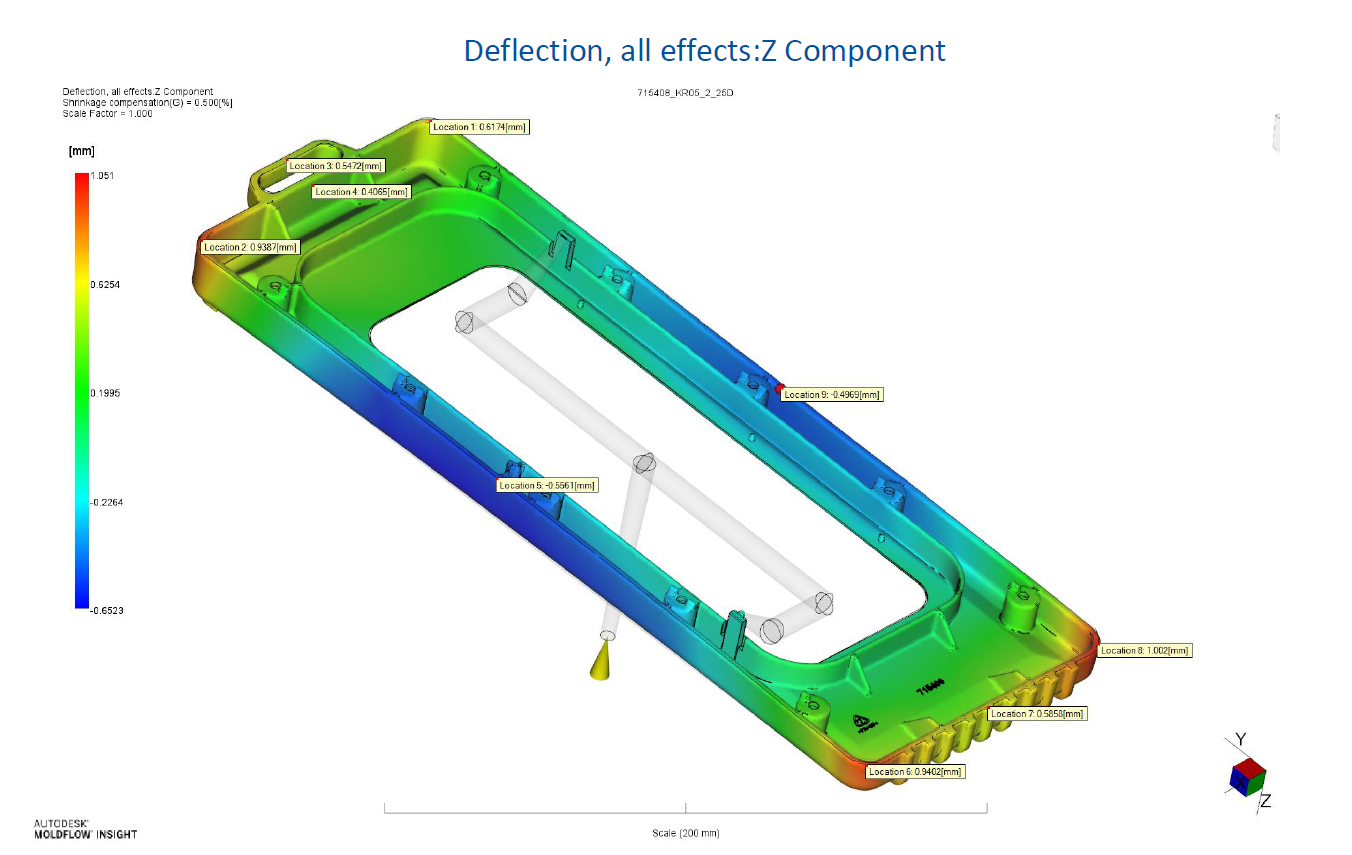

After the DFM is confirmed, we start the mold design according to the DFM and the customer’s mold specification. We will share with customers: DFM analysis report, Moldflow analysis report, 2D mold design, 3D mold design

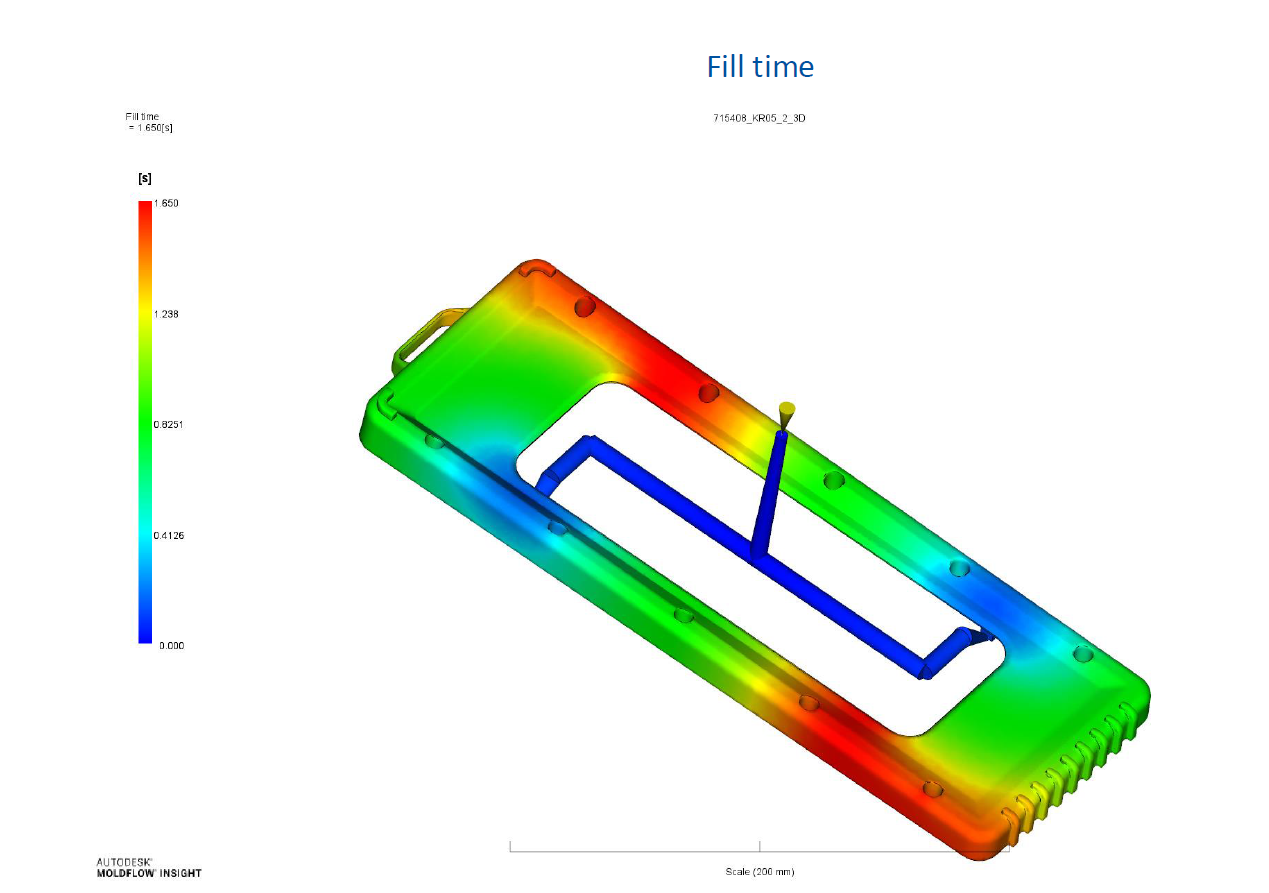

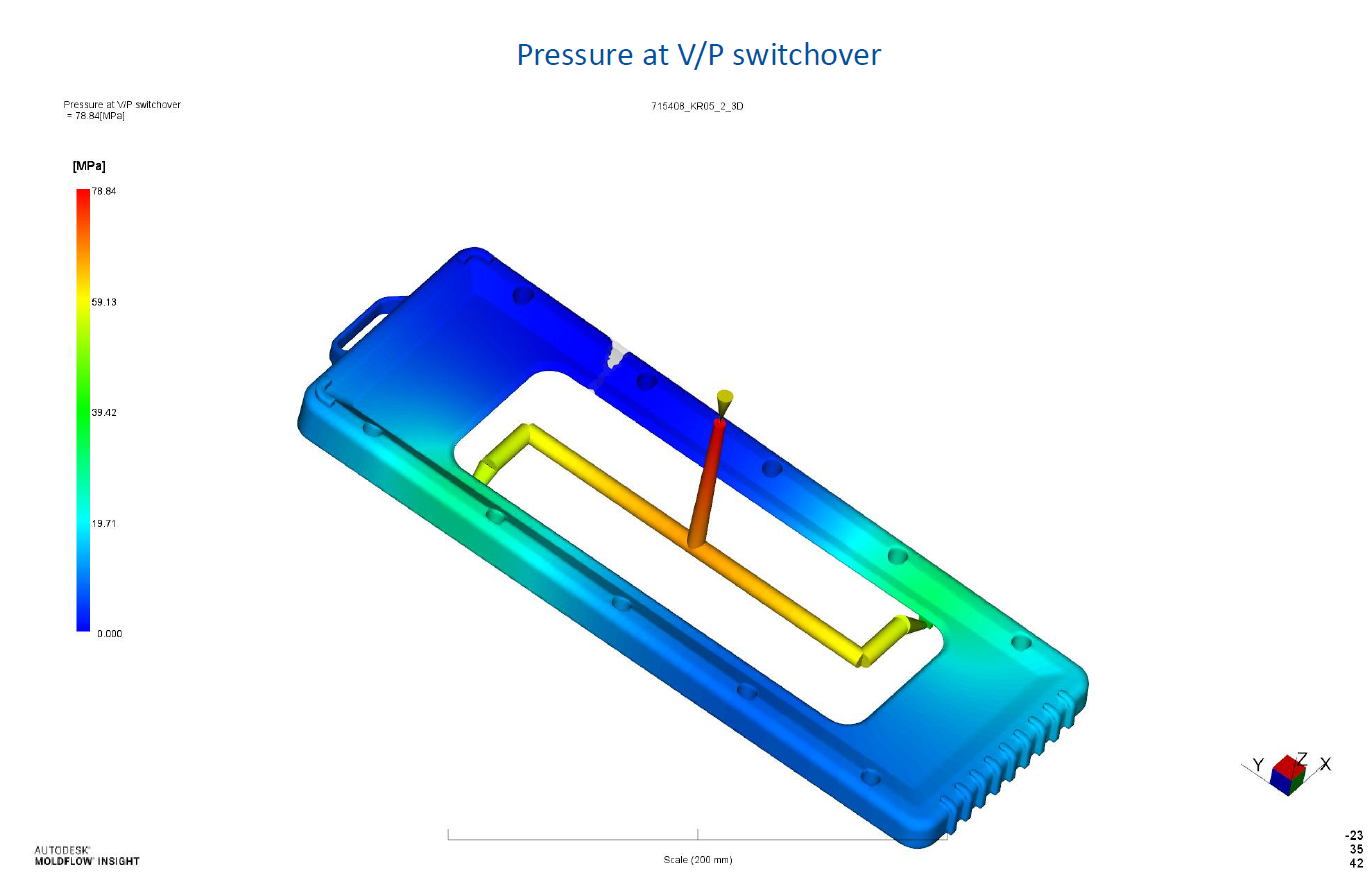

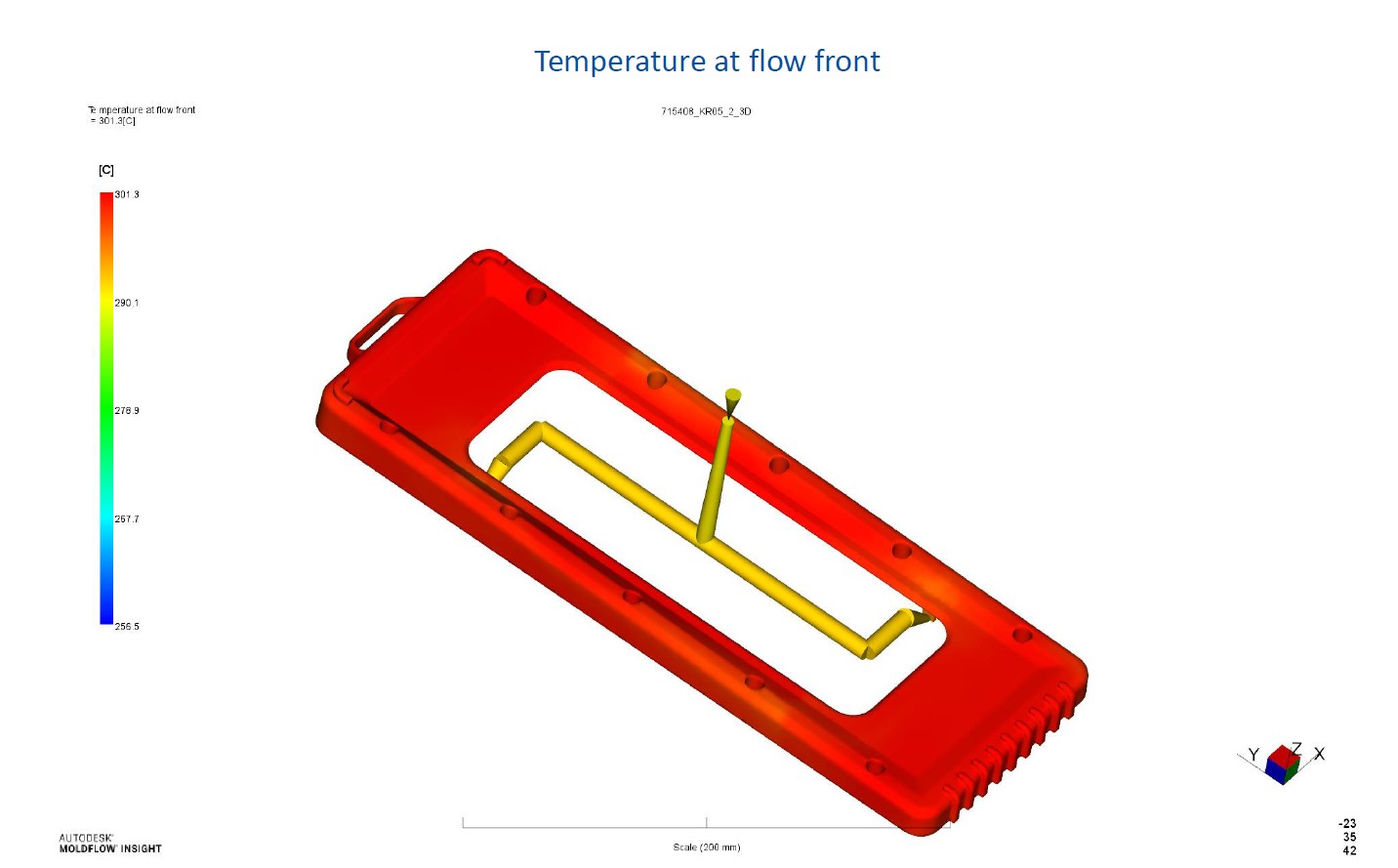

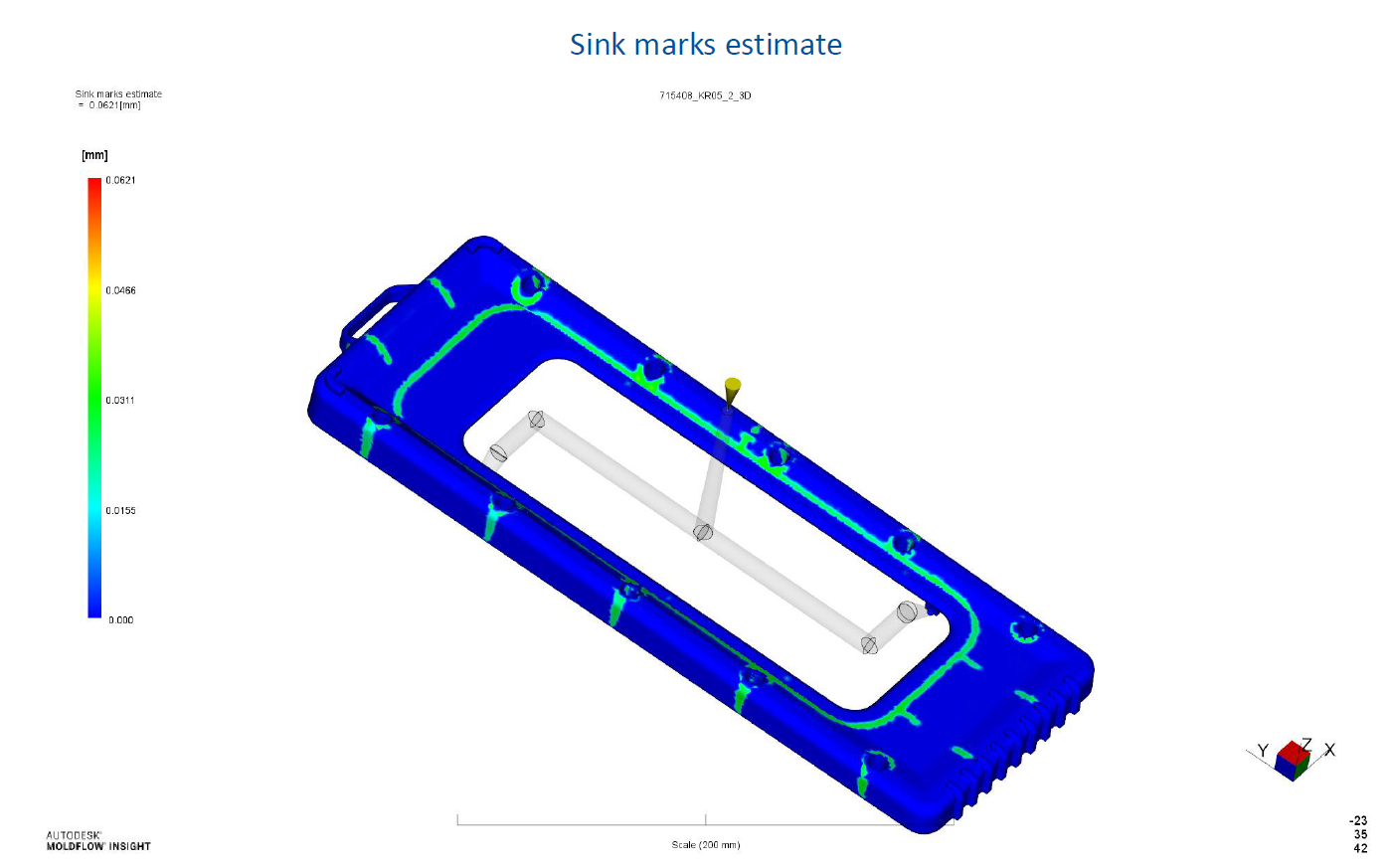

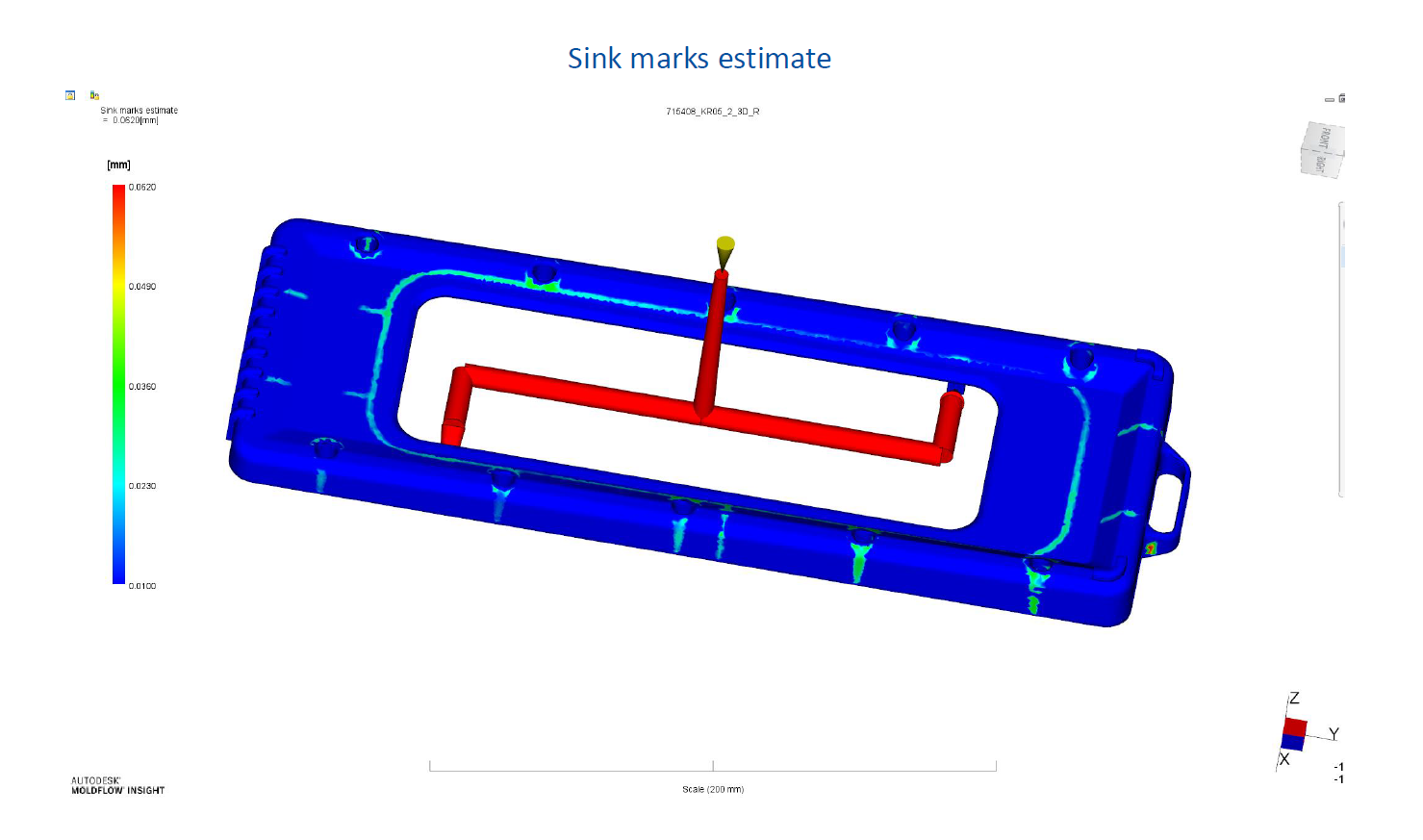

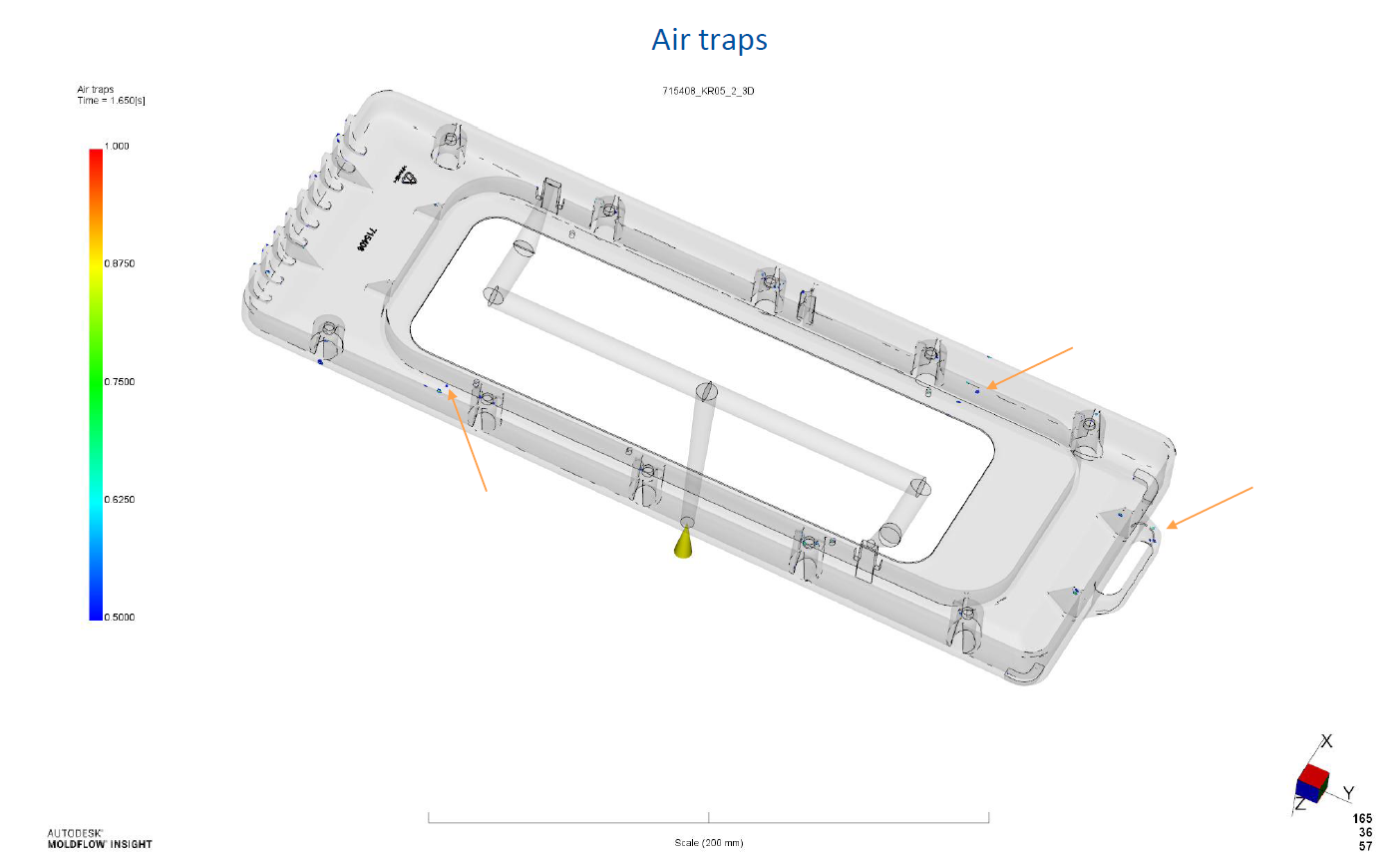

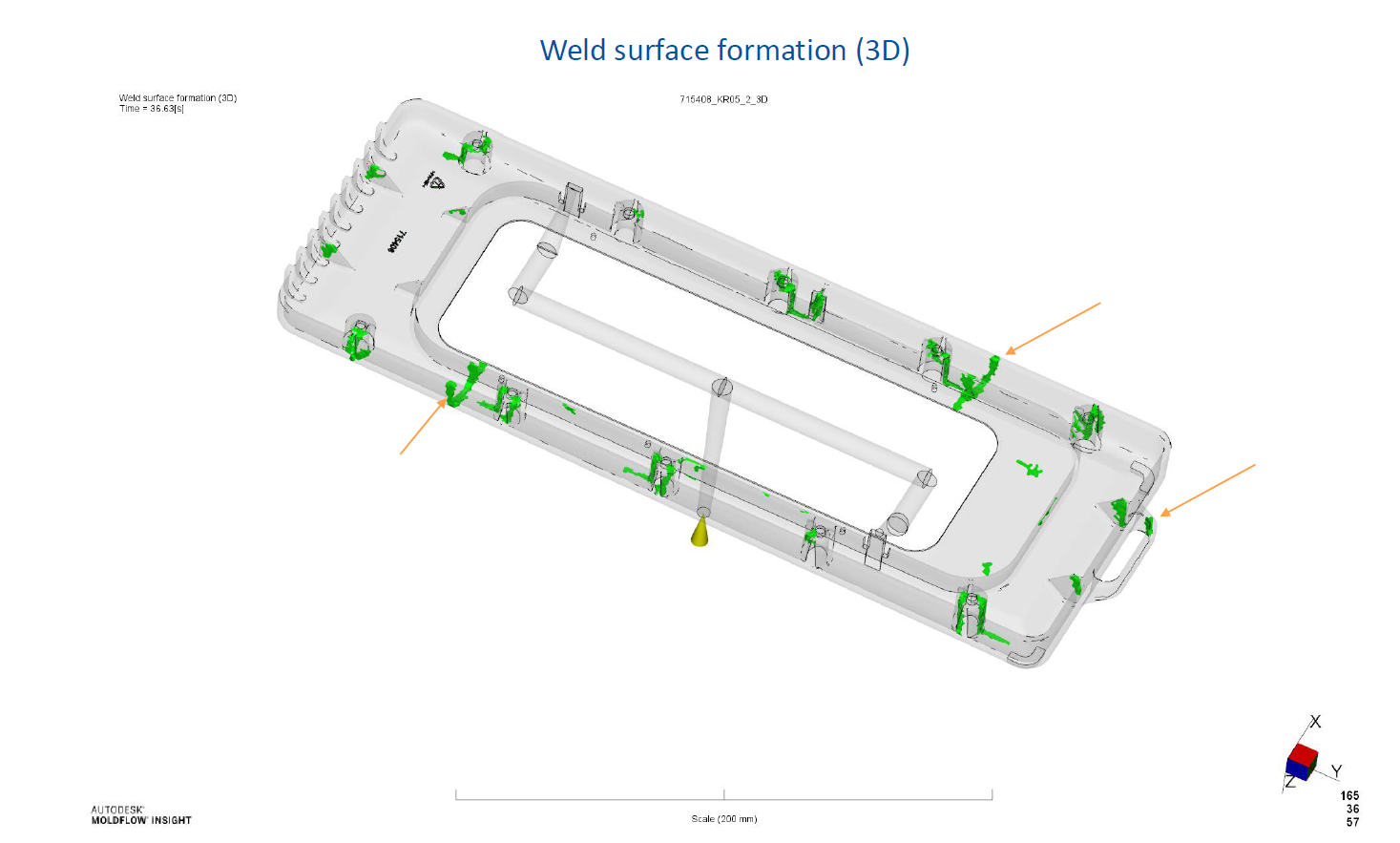

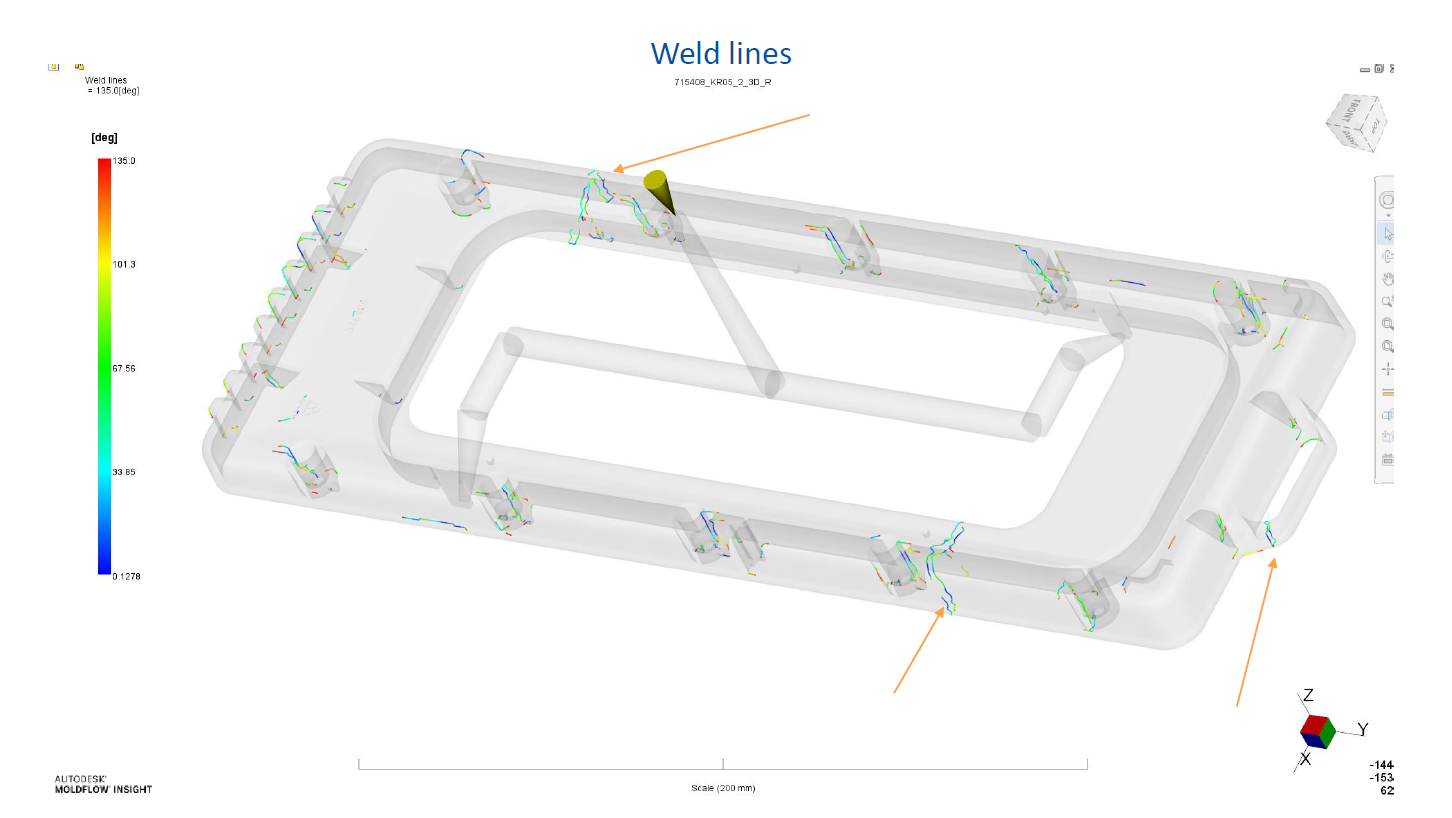

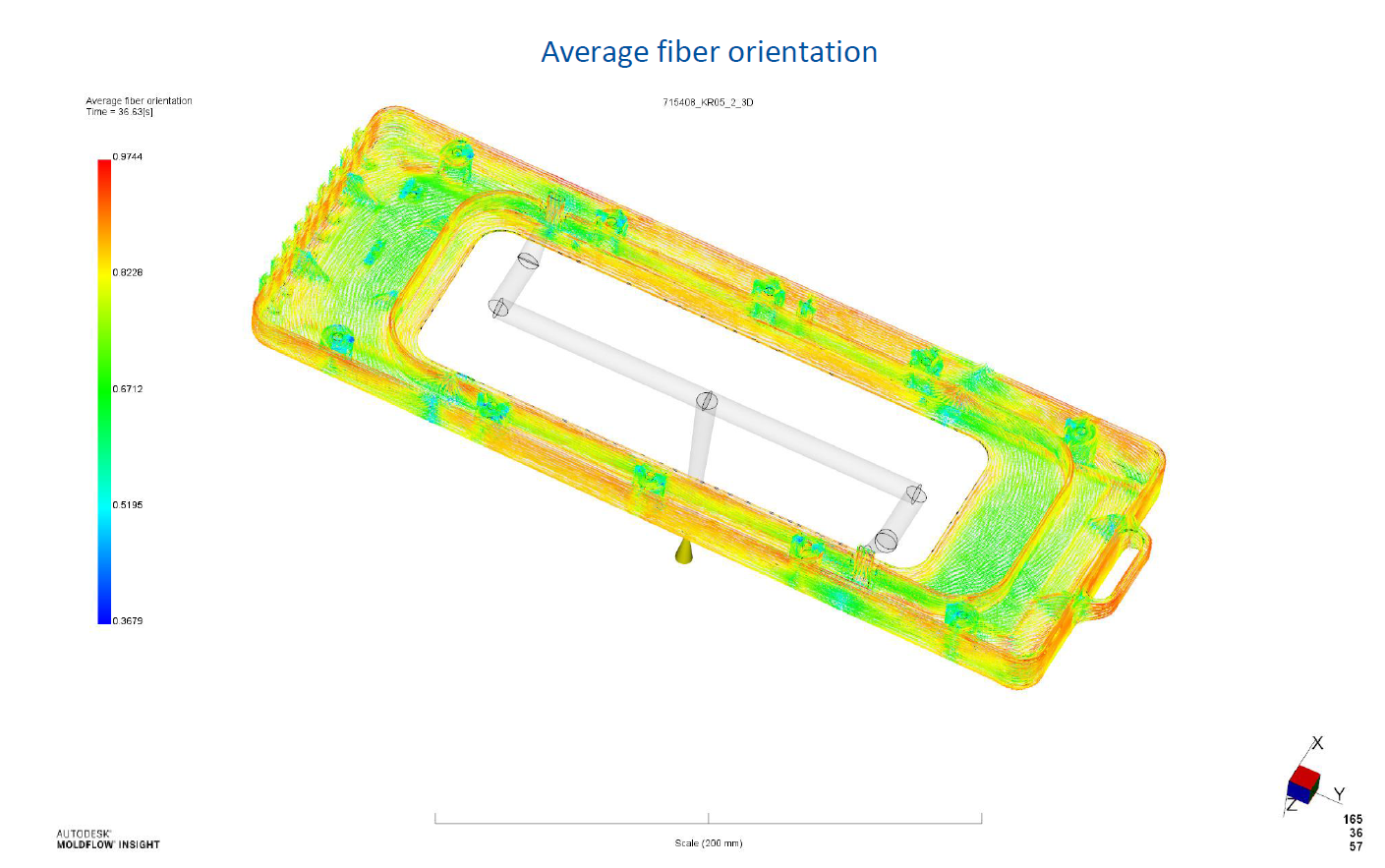

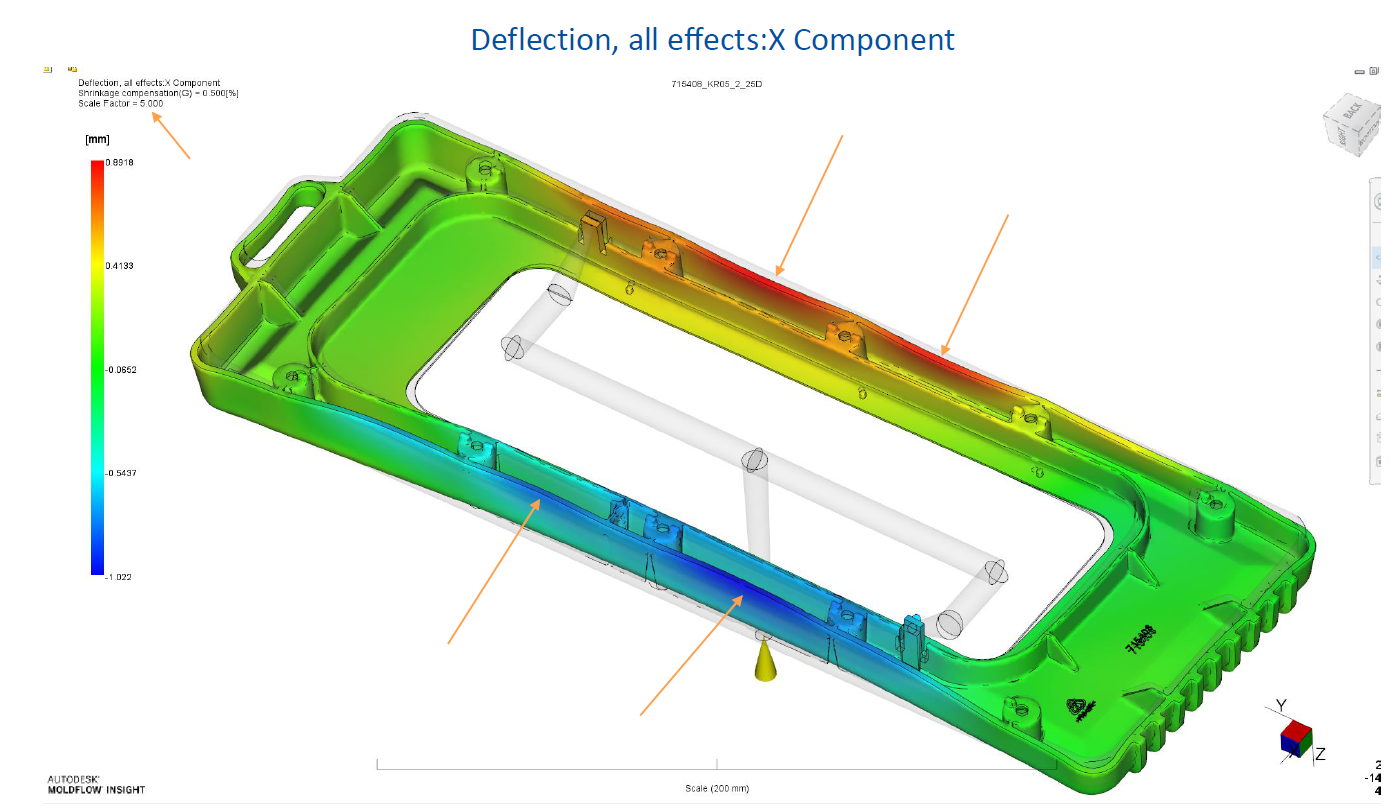

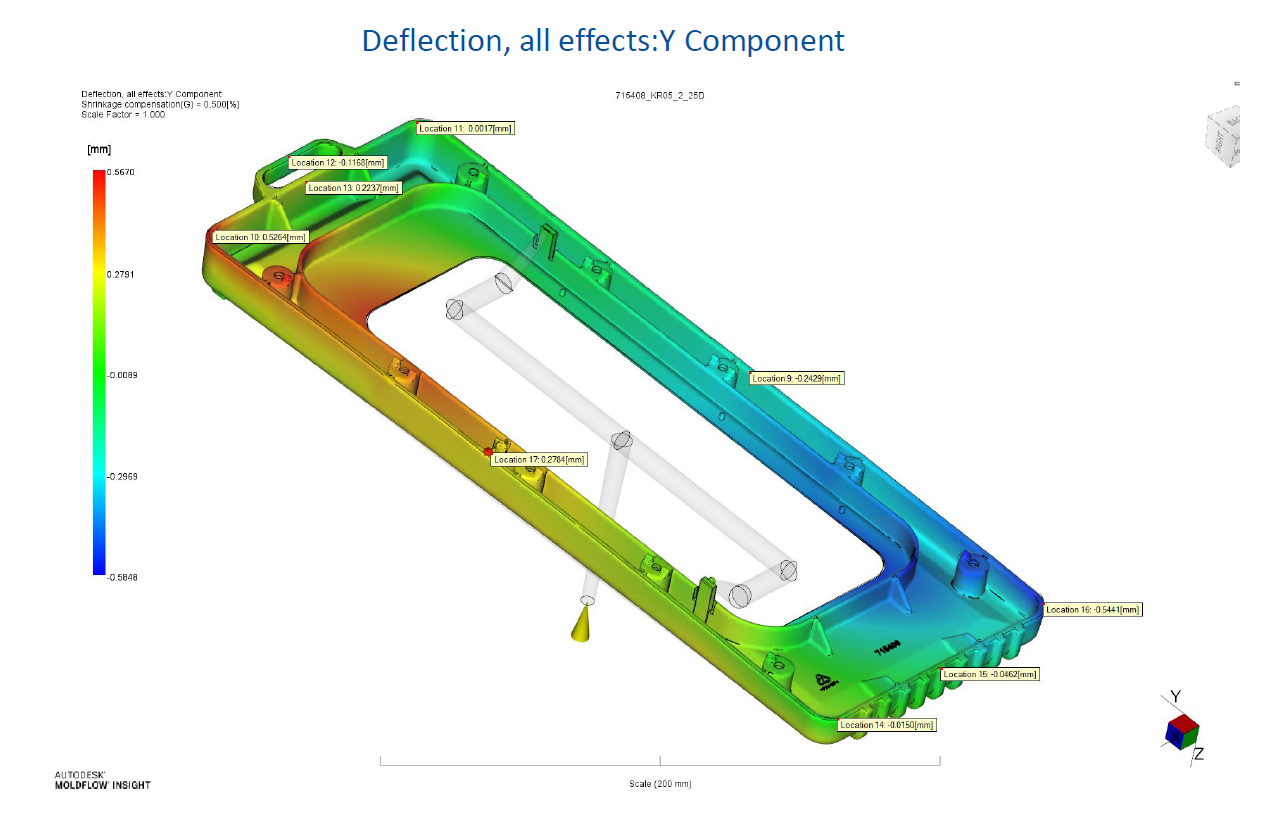

MoldFlow provides simulation tools for injection mold design. Through iterative molding simulations, our team can optimize product design, mold design, and prevent multiple mold modifications, reducing cost and time.

Detailed DFM and Moldflow Analysis will be made to define the parting line, sliders, lifters, ejectors, draft angles, injection gates, runners, and other information related to the mold design. We discussed with customer about their requirement and to check if the part needed any optimization for feasibility and to reach an agreement on how the mold will be designed.