Various surface finish selections for custom-molded plastic parts are available. Surface finishing processes for injection molding can aid in decreasing or increasing the coarseness of a part. For instance, rougher finishes are ideal for certain mechanical parts, while glossy texture fits aesthetic parts like toys.

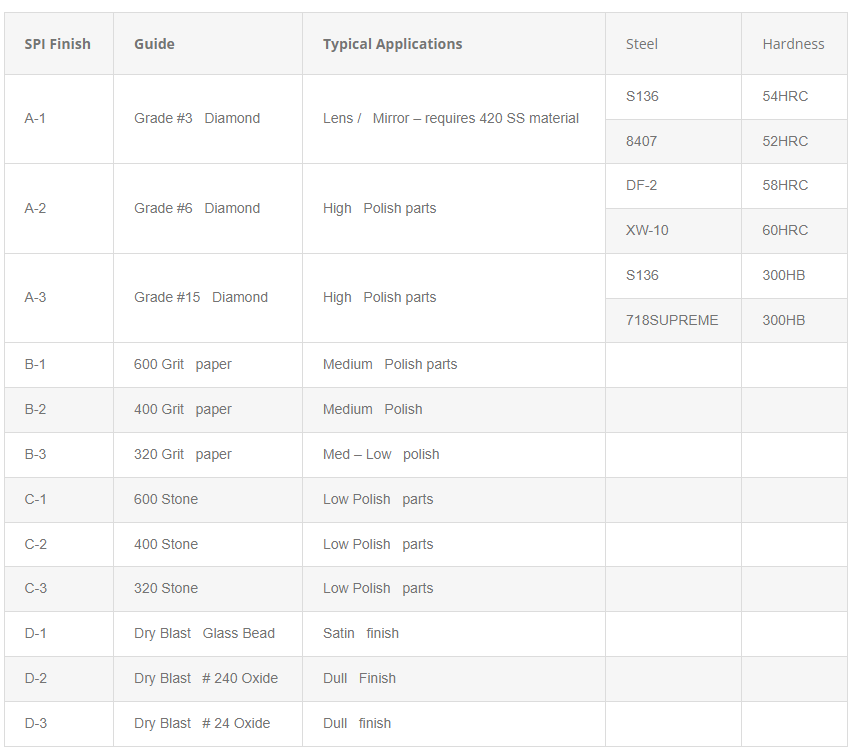

The society of plastic industry (SPI) devised industry standards for plastic injection molding finishes, The SPI surface finish standard covers 12 SPI grades of polish finishes split across four categories: glossy (A), semi-glossy (B), matte (C) and textured (D).as outlined below:

SPI A (Mirror)

It includes SPI A0,A1,A2,A3. Diamond buffing produces parts with a mirror-like finish after the mold is smoothed and polished.

SPI B (Sandpaper)

It includes SPI B0, B1, B2, B3. Fine-grit sandpaper smooths the surface of the mold, resulting in parts with a fine finish.

SPI C (Stone)

It includes SPI C1, C2, C3. To remove all machining marks, fine stone powder is used to smooth the mold.

SPI D (Sandblasting)

It includes SPI D1, D2, D3. A fine stone is polished on the mold first, and then it is sand-blasted, resulting in a sand-blasted surface.

EDM (EDM Sparking)

Standard for EDM surfaces based on CHARMILLS VDI-3400. Sparking the EDM surface is usually done using the CHARMILLS Sparking machines.

Texturing (Grain)

Normally, MoldTech and YS are used for Texturing. YS Texturing and MoldTech Texturing will handle it.

Other common finishes include the following:

· Sanding

· Anodizing

· Electroplating

· Polishing

· Power coating

· Painting

For each product color, we normally follow RaL and Pantone.